miller process gold

The Miller Process Gold

Miller process . The Miller process is an industrial-scale chemical procedure used to refine gold to a high degree of purity (99 95%) It was invented by Francis Bowyer Miller ( patented 1867) This chemical process involves blowing a stream of pure chlorine gas over and through a crucible filled with molten but impure gold Get Price

Miller Gold Refining Process by Chlorination

2016-3-24 Miller Chlorination Process In order to purify gold and remove the silver from it by any process analogous to the cementation with nitre or salt in

LBMA Miller Process

Within two years, the first full-scale plants employing the process had been successfully commissioned in the Sydney Mint and also in Auckland (gold having been discovered in New Zealand in 1861). Over the next several years, the Miller process was enthusiastically adopted by mints and refiners around the world.

High Purity Gold and the Miller Process Manhattan Gold

2012-6-7 Invented by Dr. Francis Bowyer Miller, the Miller Process was a game changer in the world of gold refining. It is popular among metal refiners all over the world because in a nut shell it’s cheap, easy, and produces high-purity gold samples about 99.95% pure gold.

Miller process ore refining Britannica

Miller’s process of refining impure gold with chlorine gas (patented in Britain in 1867) and Emil Wohlwill’s electrorefining process (introduced in Hamburg, Ger., in 1878), it became possible routinely to achieve higher purities than had been allowed by fire refining. Read More In gold processing: Refining

Leaching of gold and silver from Miller Process dross

1996-8-1 At the operating temperature of the Miller Process (about 1200) the lead and zinc chlorides are volatile and hence are removed from the liquid gold. At the end of the refining process, the slag, which mainly consists of silver and copper chlorides along with some metallic gold, is taken out and treated separately to recover the gold and silver.

miller process gold wynajmijksero.pl

miller process gold Hot Product HPC Cone Crusher Base on the latest technology and decades of years' producing experience OGG designed the After the homogenization process any NGD material destined for refining is assessed to determine between the following Miller chlorination gold refining Jul 21 &# The Miller process is a type of gold

Miller process gold fermerie

Miller process Wikipedia OverviewSee also. The Miller process is an industrialscale chemical procedure used to refine g to a high degree of purity (99.5%). It was invented by Francis Bowyer Miller (patented 1867). This chemical process involves blowing a stream of pure chlorine gas over and through a crucible filled with molten, but impure, g.

How is Pure Gold Made and Refined? Gold and

2021-1-15 The Miller process uses gaseous chlorine to extract impurities when gold is at melting point; impurities separate into a layer on the surface of the molten purified gold. The Miller process is rapid and simple, but it produces gold of only about 99.5 percent purity. The Wohlwill process increases purity to about 99.99 percent by electrolysis.

The Miller Process. Gold Refining & Metal Extraction Forum

2009-10-16 The Miller Process. Thread starter nickvc; Start date Oct 12, 2009; N. nickvc Well-known member. Joined Sep 14, 2009 Messages 4,867 Location birmingham. Oct 12, 2009 #1

The Miller Process Gold

Miller process . The Miller process is an industrial-scale chemical procedure used to refine gold to a high degree of purity (99 95%) It was invented by Francis Bowyer Miller ( patented 1867) This chemical process involves blowing a stream of pure chlorine gas over and through a crucible filled with molten but impure gold Get Price

High Purity Gold and the Miller Process Manhattan Gold

2012-6-7 Invented by Dr. Francis Bowyer Miller, the Miller Process was a game changer in the world of gold refining. It is popular among metal refiners all over the world because in a nut shell it’s cheap, easy, and produces high-purity gold samples about 99.95% pure gold.

The Miller Process Gold Org powereye

The Miller Process Gold Org. Millers fascination with technique and process emerged in his groundbreaking rediscovery in the early 1950s of granulation an ancient yet forgotten way of fusing tiny gold beads to a gold surface without solder. The fleeting creatures of earth sea and skysnails squids crabs moths and fliesbecame his muse inspiring a

Miller process gold refining equipment Manufacturer Of

Equipment miller process for gold refining. equipment for gold refining miller process pbcollege in Electrolytic Refining Mining Fundamentals AZoMining Apr 23, 2014 In the electro refining process, a block of impure metal is made the anode and a thin The Miller chlorination process is an economical refining process that separates gold of The electrolytic process is similar to gold,

Leaching of gold and silver from Miller Process dross

1996-8-1 Leaching of gold and silver from the Miller Process dross was investigated using non-cyanide leachants. The dross was found to be very refractory to direct leaching with thiourea as well as thiosulphate. Thiourea leaching of the calcined dross resulted in about 84% extraction of gold, but the leaching of silver was very poor.

How is Pure Gold Made and Refined? Gold and

2021-1-15 The Miller process uses gaseous chlorine to extract impurities when gold is at melting point; impurities separate into a layer on the surface of the molten purified gold. The Miller process is rapid and simple, but it produces gold of only about 99.5 percent purity. The Wohlwill process increases purity to about 99.99 percent by electrolysis.

miller process gold wynajmijksero.pl

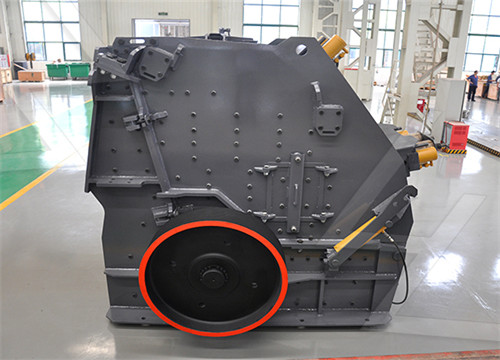

miller process gold Hot Product HPC Cone Crusher Base on the latest technology and decades of years' producing experience OGG designed the After the homogenization process any NGD material destined for refining is assessed to determine between the following Miller chlorination gold refining Jul 21 &# The Miller process is a type of gold

Miller Chlorination process Gold Refining & Metal

2019-8-22 I'm doing a research on gold refinning processes available in market. I have not found any figure, drawing, schem or flowchart of the miller chlorination process. As I know there is a lot of people who understand a lot about gold refinning here, is tere anyone who could send me a picture, a schem, a draw, anything? Thanks a lot..

The Miller Process. Gold Refining & Metal Extraction Forum

2009-10-16 The Miller Process. Thread starter nickvc; Start date Oct 12, 2009; N. nickvc Well-known member. Joined Sep 14, 2009 Messages 4,867 Location birmingham. Oct 12, 2009 #1

Training Millerheimangroup Academy

The programme then delivers a process to document long-term plans for managing key accounts and allocating resources efficiently. As a result of adopting this process, account managers will craft strategies for managing cross-functional teams to clarify roles and responsibilities, boost collaboration, and ensure accountability.

The Miller Process Gold

Miller process . The Miller process is an industrial-scale chemical procedure used to refine gold to a high degree of purity (99 95%) It was invented by Francis Bowyer Miller ( patented 1867) This chemical process involves blowing a stream of pure chlorine gas over and through a crucible filled with molten but impure gold Get Price

the miller process gold org adca

31-12-2018 Gold processing Gold processing The Miller process is based on the fact that virtually all the impurities present in gold combine with gaseous Miller process chemeurope Miller process The Miller process is an industrial-scale chemical procedure used to refine gold to a high degree of purity (99.95%).

Miller Process Of Gold Refining Consultant

2021-6-23 Miller Process Of Gold Refining Consultant. The Two Gold Refining Methods Most Commonly Employed To Derive Pure Gold Are The Miller Process And The Wohlwill Process The Miller Process Uses Gaseous Chlorine To Extract Impurities When Gold Is At Melting Point Impurities Separate Into A Layer On The Surface Of The Molten Purified Gold Online Chat

Miller process gold fermerie

Miller process Wikipedia OverviewSee also. The Miller process is an industrialscale chemical procedure used to refine g to a high degree of purity (99.5%). It was invented by Francis Bowyer Miller (patented 1867). This chemical process involves blowing a stream of pure chlorine gas over and through a crucible filled with molten, but impure, g.

Leaching of gold and silver from Miller Process dross

Leaching of gold and silver from the Miller Process dross was investigated using non-cyanide leachants. The dross was found to be very refractory to direct leaching with thiourea as well as thiosulphate. Thiourea leaching of the calcined dross resulted in about 84% extraction of gold, but the leaching of silver was very poor.

The Miller Process. Gold Refining & Metal Extraction Forum

2009-10-16 The Miller Process. Thread starter nickvc; Start date Oct 12, 2009; N. nickvc Well-known member. Joined Sep 14, 2009 Messages 4,867 Location birmingham. Oct 12, 2009 #1

miller process gold wynajmijksero.pl

miller process gold Hot Product HPC Cone Crusher Base on the latest technology and decades of years' producing experience OGG designed the After the homogenization process any NGD material destined for refining is assessed to determine between the following Miller chlorination gold refining Jul 21 &# The Miller process is a type of gold

Miller Process Gold Refining In Lahore Pakistan

Miller Process Gold Refining In Lahore Pakistan Grinding. Miller process gold refining in lahore pakistan miller process gold refining in lahore pakistan if you want to get more detailed product information and prices zme recommend that you get in touch with us through learn more bible study on refining process gold

Gold Melting Furnace, CE Approved Gold

2022-3-16 Miller process is a chlorination method that reduces the impurity level of gold to about 99.5%. This process simply involves the passing of chlorine over molten gold. On contact with the gold, the impurities trapped in the gold form

Fire Assay Gold SGS

process for obtaining analytical gold and platinum group element (PGE) data from high grade ores. It is a modernized process but in its simplest form, has been in use for centuries. Fire assaying is used in the determination of gold in all sample types, including drill core, soil and chip

- мелющие анимация шаровой мельницы

- Малайзийский подвижной известняк ударная дробилка цена

- Индонезийская глинобитная дробилка

- чулуу бутлах бутлах машин

- воздушный измельчитель

- бутлуурын марк desighn

- используется дробилка небольшого портативного

- линейная мельница

- б доломит поставщик дробилка в нигерии

- дробильная установка

- используется железорудный производитель щековая дробилка в Нигерии

- мрамор дробильная установка в Пакистане

- Китаи роторная дробилка оборудование

- боржин чулууг хайрга болгон бутлах машин

- киргизская компания по дроблению и добыче полезных ископаемых

- инструмент строительное оборудование

- michine для каменная дробилка

- кукурузная дробилка на продаже

- бентонит дробилки и мельницы в Украина

- щековая дробилка щебнягранита цена

- дробление золотой руды

- Австралид борлуулах зорилгоор ашигласан бутлуур

- мельница мельник купить барнаул

- молотковая дробилка руды дробилка для продажи

- vsi элс боловсруулах үйлдвэр